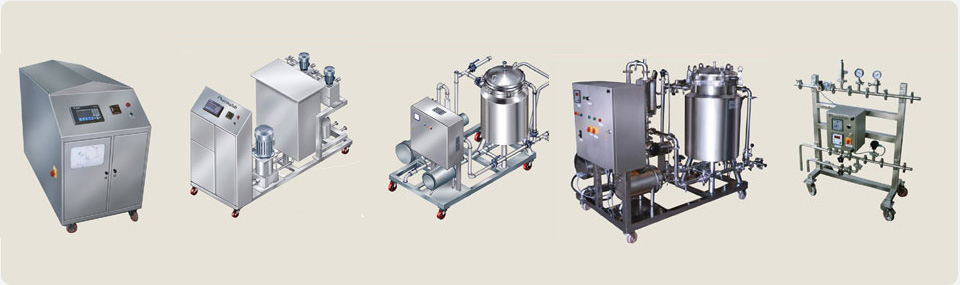

Our Products

-

Purified Water Generation SystemThe units are custom made, modular,...

Purified Water Generation SystemThe units are custom made, modular,... -

Storage & Distribution SystemVarious items of equipments & fitments...

Storage & Distribution SystemVarious items of equipments & fitments... -

RO Water Tanks / Purified Water Tanks / WFI Tanks & Process VesselsWide experience in Design, Manufacture, Supply,...

RO Water Tanks / Purified Water Tanks / WFI Tanks & Process VesselsWide experience in Design, Manufacture, Supply,... -

CIP/SIP SystemInstall Mobile and Fixed CIP & SIP Units...

CIP/SIP SystemInstall Mobile and Fixed CIP & SIP Units... -

Sterile Pressure & Filling Vesselscomplete range of Aseptic and sterile SS containers ...

Sterile Pressure & Filling Vesselscomplete range of Aseptic and sterile SS containers ... -

Parenterals PlantsInnovative and efficient process technology for Parenterals ...

Parenterals PlantsInnovative and efficient process technology for Parenterals ... -

Injectables PlantsInnovative and efficient process technology for injectable plants applications ...

Injectables PlantsInnovative and efficient process technology for injectable plants applications ... -

Liquid Manufacturing Plant Manufacture and install quality Liquid Oral Plant (Syrups & Suspensions) ...

Liquid Manufacturing Plant Manufacture and install quality Liquid Oral Plant (Syrups & Suspensions) ... -

Ointment /Cream mfg. PlantManufacture and supply the complete customized automated Ointment / Cream manufacturing Plant ...

Ointment /Cream mfg. PlantManufacture and supply the complete customized automated Ointment / Cream manufacturing Plant ... -

Spares, Consumables & ServicesPPPL offers various Spares Consumables & Services as per required...

Spares, Consumables & ServicesPPPL offers various Spares Consumables & Services as per required...

CIP/SIP System

We design, develop, manufacture, supply and install Mobile and Fixed CIP & SIP Units for sanitization and sterilization.

CIP/SIP SYSTEMS

CIP/SIP SYSTEMSThe units are custom made, modular, skidded in automated or semi-automated Models as per the required time cycle for cleaning and sterilization as a part of cGMP requirements from portable to large fixed Multi-Tank system.

Scope of CIP Unit:

Scope of CIP Unit:

- CIP Tank/Tanks, Jacketed/Non-Jacketed

- Supply Pump/Return Pump

- Heater as required

- Dosing Tanks/Pumps

- Inter-connected Pipings/Valves/Instrumentation

- Automation System/Control Panel

- SS Skid/SS Platform

Scope of Mobile SIP Unit & Features:

Scope of Mobile SIP Unit & Features:

- Pure Steam Header with PI, TI & Safety Valve

- Condensate Header with sterile steam traps unit and Temp. Sensor

- PLC Control Panel with Time / Temperature control program, printer, alarm etc. as required

- SS Mobile Stand with PU Castors

- Features encompassed with the system like meeting designing to cGMP criteria; orbital welding; automation as per MCA & USFDA 21 CFR Part 11 with 100% drain ability design criteria.

- Documented output of cleaning & sterilization cycles.

- The CIP System controls the cleaning “T.A.C.T” parameters of Temperature, Action (velocity / pressure), Chemical concentration and Time of exposure.

Our Products

-

Purified Water Generation System

Our In-house design & engineering and manufacturingfacilities

Complete system solution available from one source. -

Storage & Distribution System

A unit which works as polishing unit for “High Purity Water Application”.

Adapted system permit compact design. -

CIP/SIP System

A well designed CIP/SIP system employing technology and a bit of process integration will facilitate you to clean one part of the plant while other areas maintain to produce product.

-

Liquid Manufacturing Plant

The Liquid Manufacturing Plants are ideal tools for the pharmaceutical industry for the production of Oral Liquids.

-

Ointment /Cream mfg. plant

Equiped with CIP & SIP facilities.

Dual Speed Anchor Agitator

Plants available with Fully/Semi Automatic systems.